This page is full of info that has been acquired through taking these beautifully engineered vehicles to extremes most would never dream. Also some info will be things learned at the racetrack, whether it’s our own local F1 series or events across the country and world. Any questions or info you would like to see on this page email Sandy at sandy@molzermoweryracing.com |

3 Shoe adjustable Clutch 4415/4416

When installing a 3 shoe adjustable clutch to your model you must drill a hole in the clutch bell to make adjustments without removing the motor. You need to drill a 4mm hole in the clutch bell. It should be drilled 10mm from the inside edge (closest to motor) on 1/5 scale models. 7mm on 1/6 scale models

|

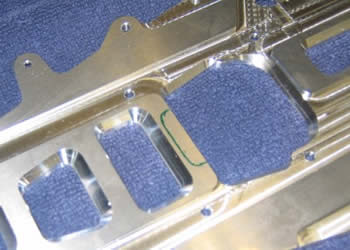

F1 Comp car Samba pipe installation. When installing a Samba tuned pipe on a FG F1 Comp car there is a very tight fit between the header/pipe and the chassis. To solve this we remove a small portion of the cross member in the chassis. There is plenty of material and strength in that area. Make a pen mark.

Then use a 1/2 in. Dremel sanding drum to remove the material slowly.

Then recheck clearance and your set.

|

04 Shocks We have seen some issues with the new style threaded shock bodies on the sedans and F1’s becoming stuck. People have tried different ways of cleaning them with little success. What this is is called "galling". The tolerances are very tight and when the same material is used for both the shock body & collar they bind. The way we keep this from happening is to apply a light thin coat of anti-seize lubricant. Add a thin coat with a small paint brush on the threads, when the ring is put on, there will still be enough on the threads. If you use a cleaner on them after use reapply anti-seize. |